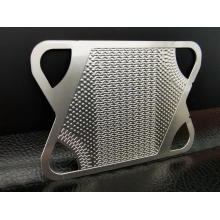

Plate Heat Exchanger for Sterilizaer Processing and Milk Processing Pasteurization (BR03K-1.0-18-E)

Basic Info

Model No.: BR03K-1.0-18-E

Product Description

Model NO.: BR03K-1.0-18-E Customized: Customized Trademark: Jiema Origin: Guangzhou, China Application: Milk, Yogurt, Milk Powder, Cheese Size and Material: Can Be Worked as Per Client Requirement Parameter Specification: ISO9001: 2008, SGS HS Code: 841950009 Plate Heat Exchanger for Sterilizaer Processing and Milk Processing Pasteurization(BR03K-1.0-18-E)

Jiema Company have developed and manufactured Plate Heat Exchanger and PHE Plate , Gasket , and related spare parts since 2005 , With decades of year experience, Our Plate Heat Exchanger details as below :

Features :

1, High Efficiency

2, High Heat Transfer Rates

3, Modularity For Flexibility

4, Compact Design

5, Self-Cleaning Action

6, Easy to maintance

Component Materials:

Heat-exchange plate: SUS304, SUS316L, SMO254, titanium, nickel, Hastelloy alloy

Gasket seal: NBR, H-NBR, EPDM, food pad, fluorine rubber, silicon rubber

Frame: Carbon steel, stainless steel, coated stainless steel

Clamping bolt: Galvanized carbon steel, stainless steel

Interface: Rubber, carbon steel, stainless steel

Guide bar: Galvanized carbon steel, stainless steel

How does a Plate Heat Exchanger Work?

Each unit consists of a series of grooved plates that are individually gasketed and pressed tightly together by compression bolts within a frame. Fluids enter and exit the PHE through portholes in one or both ends of the frame. Within the unit, the fluid to be heated or cooled flows down one side of each plate, while the heating or cooling medium flows in the opposite direction across the Other side. The huge temperature difference created by these opposite flows allows maximum heat transfer efficiency for closest possible approach temperature .

About Warranty

We promise 10 year guarantee, all reasonable relevant cost will be undertaken by us in the first year if our heat exchanger fail to work due to quality problem, only the free repairing operation guide is available in the rest of the 9 years via E-mail /Fax/Phone

Making Procedure :

Parts of visited clients :

Contact us if you need more details on Plate Heat Exchanger. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Heat Exchanger Gasket、Induction Heater. If these products fail to match your need, please contact us and we would like to provide relevant information.

Jiema Company have developed and manufactured Plate Heat Exchanger and PHE Plate , Gasket , and related spare parts since 2005 , With decades of year experience, Our Plate Heat Exchanger details as below :

Features :

1, High Efficiency

2, High Heat Transfer Rates

3, Modularity For Flexibility

4, Compact Design

5, Self-Cleaning Action

6, Easy to maintance

Component Materials:

Heat-exchange plate: SUS304, SUS316L, SMO254, titanium, nickel, Hastelloy alloy

Gasket seal: NBR, H-NBR, EPDM, food pad, fluorine rubber, silicon rubber

Frame: Carbon steel, stainless steel, coated stainless steel

Clamping bolt: Galvanized carbon steel, stainless steel

Interface: Rubber, carbon steel, stainless steel

Guide bar: Galvanized carbon steel, stainless steel

How does a Plate Heat Exchanger Work?

Each unit consists of a series of grooved plates that are individually gasketed and pressed tightly together by compression bolts within a frame. Fluids enter and exit the PHE through portholes in one or both ends of the frame. Within the unit, the fluid to be heated or cooled flows down one side of each plate, while the heating or cooling medium flows in the opposite direction across the Other side. The huge temperature difference created by these opposite flows allows maximum heat transfer efficiency for closest possible approach temperature .

About Warranty

We promise 10 year guarantee, all reasonable relevant cost will be undertaken by us in the first year if our heat exchanger fail to work due to quality problem, only the free repairing operation guide is available in the rest of the 9 years via E-mail /Fax/Phone

Making Procedure :

Parts of visited clients :

Contact us if you need more details on Plate Heat Exchanger. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Heat Exchanger Gasket、Induction Heater. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plate Heat Exchanger > Others Plate Heat Exchanger

Premium Related Products

Other Products

Hot Products

Shell and Tube Heat Exchanger as EvaporatorReplacement Gea Plate Heat Exchanger GasketAir Radiator Tube for Air Dehumifying (SRGG-4-30)Copper Tube Air Heat Exchanger for Condenser (SZGG-4-20)direct factory plate and bar marine aftercoolerbar&plate marine heat exchangerhydraulic combined air to oil cooler for agricultural machinerywind turbine oil air cooler radiator manufacturerNew Products Bar and Plate Aluminum Atlas Copco Air Coolermanufacturer of plate fin aluminum oil radiator fanDirect Supplier Of Aluminum Plate Fin Cooler FanManufacturer Of Alumnum Plate Fin Water Air Intercooler CoreDirect supplier of aluminum plate fin oil air heat exchangerchina supplier direct factory plate fin aluminum water to air coolerDirect supplier of aluminum plate fin heat exchanger for hydraulicHot Selling Customized Aluminum Heat Exchanger Core In Aluminum Material